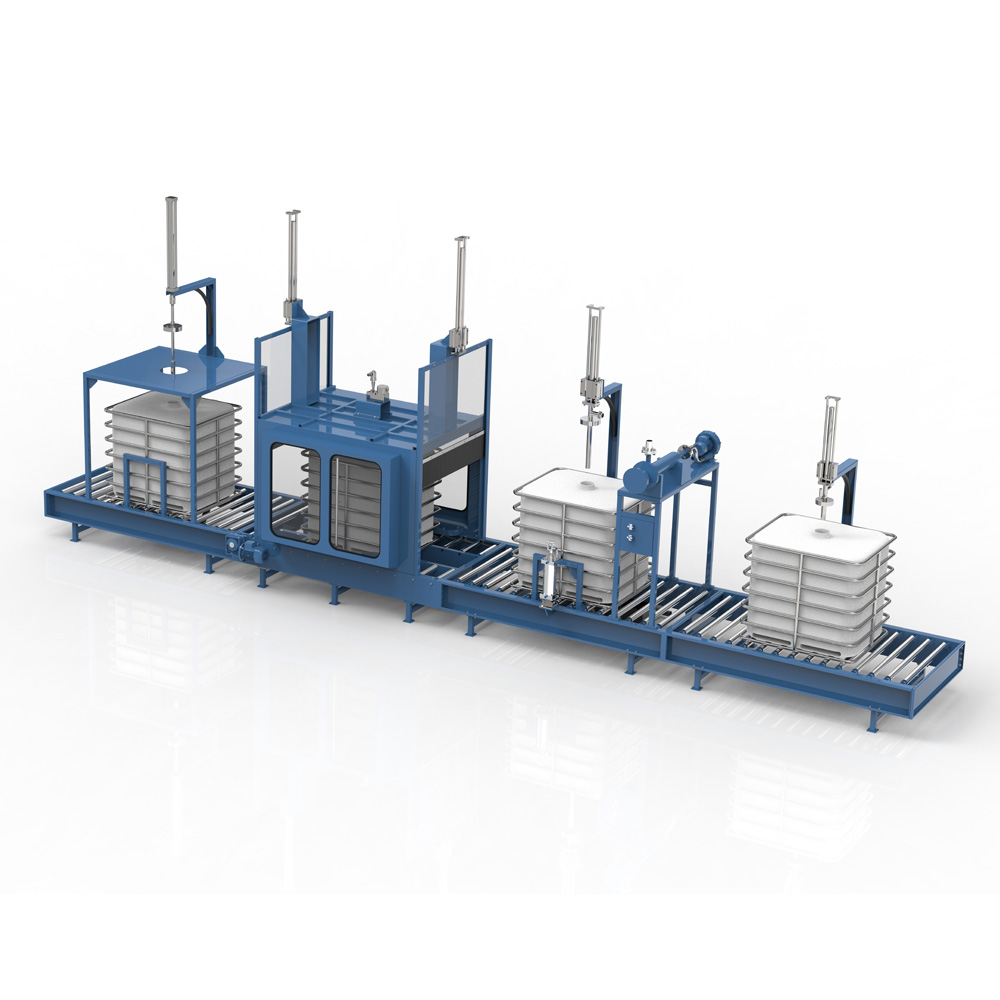

Fully Automatic IBC Tank Cleaning System

Features:

Powerful Mechanical Action of the IBC Tank Cleaning System

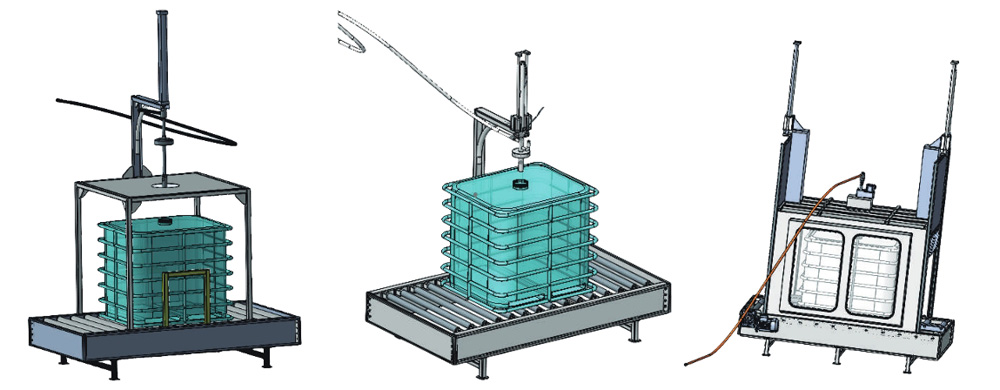

The system combines high pressure and flow rate to generate an intense impact jet, delivering several times the cleaning force of conventional products. This enables longer cleaning distances and wider coverage areas. The high-pressure pump boosts water kinetic energy, effectively removing residues from the container walls. Direct impact in the vertical direction helps break through stubborn contamination, while tangential forces assist in scraping residues off the container surface.

Minimal Leakage and High Efficiency

With only 3% leakage, 97% of the cleaning liquid is effectively used for cleaning. This allows the 3D rotary spray head to fully utilize mechanical force, greatly reducing dependency on cleaning time, chemical reactions, and temperature. Compared to similar products, the IBC 3D cleaning head consumes only 20–50% of water, time, and energy.

True 3D Cleaning

The system provides a precise, fully repeatable, and tightly guided spray pattern for complete 360° spherical coverage. Cleaning is completed in just 2–5 minutes, reducing downtime for IBC tanks. It also lowers resource consumption, cuts wastewater treatment costs, and ensures thorough cleaning. This reduces the use of chemicals and minimizes environmental impact.

Standardized Equipment Configuration

All components are precisely machined, and parts within the same model are highly interchangeable, ensuring easy maintenance and consistently high cleaning performance.

Advantages:

Custom-designed based on client requirements, with fully automated internal and external cleaning, disinfection, and drying. Easy to operate, stable in performance, and highly efficient.

Cleaning time per barrel is approximately 2–5 minutes, significantly saving manpower and resources, improving production efficiency, and reducing labor intensity.

Effectively solves the difficulty of hiring cleaning staff, greatly improves the working environment, and is more environmentally friendly.

The system supports optional high, medium, or low-pressure cleaning modes, meeting the needs of various working conditions.

Equipped with a precision 360° full-coverage high-pressure 3D cleaning head, providing strong impact force with low liquid consumption.

Requires only 1–2 operators, offering excellent economic benefits. The investment cost can be quickly recovered while significantly improving both quality and production capacity.

| Max Flow(L/min) | 20 |

|---|---|

| Max Pressure(bar) | 120 |

| Power | 16KW |

| Power Supply | 380V 50HZ |

| Max Cleaning Diameter | 16.4′ |

| Water Inlet | G1-1" |

| Water Outlet | G1-3/4 |

| Device Dimensions | 1800mm x 2950mm x 10000mm |

| Weight | 2800KG |

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert