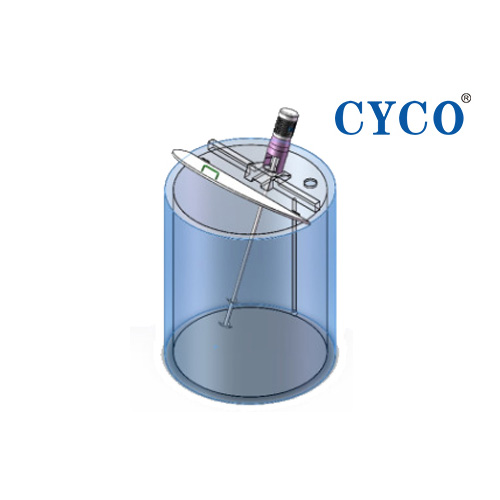

Fully Automatic Cleaning System for Mixing Drums

The CYCO mixing drum cleaning system integrates high-pressure water jet technology, a 3D rotary cleaning nozzle, and a lifting mechanism. The system can be flexibly configured to clean both the interior and exterior of the drum, or just the inside, providing thorough 360° cleaning with no dead angles.

The high-pressure water jet generates powerful impact force, effectively removing concrete residues, dirt, and other contaminants from the inner wall and mixing shaft of the drum.

The 3D rotary cleaning nozzle operates under water pressure and rotates automatically to deliver close-range, full-coverage cleaning of the drum’s interior surfaces.

Equipped with a lifting mechanism, the nozzle’s position can be adjusted based on the drum’s height and cleaning requirements to ensure optimal results.

The system uses minimal water, and the wastewater can be collected and recycled, reducing water consumption. With low power consumption throughout the cleaning process, the system supports energy-saving and environmentally friendly operations.

Technical Specifications

Working Pressure: Depends on model and configuration; typically up to 1000 bar (100 MPa).

Flow Rate: Varies based on system setup and cleaning requirements; generally ranges from tens to hundreds of liters per minute.

Cleaning Time: Determined by drum size, contamination level, and cleaning standards; usually completed within a few to several dozen minutes.

Power Consumption: Very low, typically around 0.02 kWh per cleaning cycle.

Applications

The mixing drum cleaning system is widely used in the construction, chemical, environmental, food, and pharmaceutical industries for cleaning mixing drums, reactors, storage tanks, and similar equipment.

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert