DCF-M Dual-Fluid Solenoid Valve Nozzle

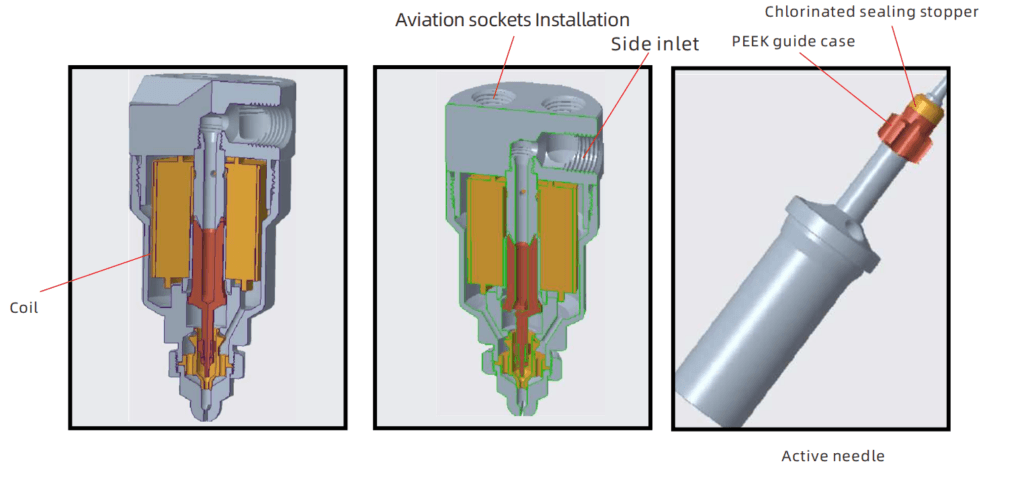

The DCF-M dual fluid solenoid valve nozzle (air atomizing model) is a high velocity, solenoid atomizing nozzle. When properly installed, operated and maintained, it can be used in Zone 1 rated hazardous areas. The wetwares are constructed of stainless steel, polyphenylene sulfide (PPS), polyetheretherketone (PEEK), and fluoroelastomer (FFKM) for superior temperature and chemical resistance.

DCF-M dual fluid solenoid valve nozzles can open/close quickly. When you need 180 times/minute or 10,000 or more, you can find what you need in our large-scale spray nozzle production line. Options include adjustable or standard automatic spray nozzles, metering nozzles, compact precision nozzles, clear needles, mounting configurations and more. For more complex control of our automatic spray nozzles, add a spray control system to optimize performance and significantly increase cycle speed.

Maximum voltage: DC24V

Case active core: 430F stainless steel

Maximum current: 0.75A

Spring: 304SS

Maximum pressure: air pressure 100PSL, water pressure 60PSI

Rubber ring: EPDM and fluorinated rubber

Maximum flow: 0.47GPM at 100PSI

Coil: nylon rubber coating

Liquid inlet: 1/4

Plastic parts: Teflon

Maximum temperature resistance: 60℃

Wire: PUR material

Maximum switching frequency: 1000 times/minute

Advantages

1. The electric air atomizing nozzle has a built-in 24V DC solenoid coil and does not require compressed air;

2. The pneumatic hydraulic spray nozzle is specially designed for precise dispersion and metering of pressurized liquids;

3. The electric hydraulic spray nozzle uses a built-in 24V DC solenoid coil;

When you need precise spraying, moisturizing, and preservative operations, the 2205-A automatic spray control system is an ideal choice, with air atomization and electric/pneumatic hydraulic types. When using the Changyuan automatic spray control system, precise spray control can achieve automatic flow adjustment control according to changes in production line speed.

Fluid Connections

Fluid connections should be made using appropriate 1/4″ pipe connections. If metal fittings are used, an appropriate thread sealant should be applied to the threads prior to assembly. For those applications where recirculation is required, two 1/4″ pipe connection ports are provided. If recirculation is not required, one of the doors should be plugged using the 1/4″ pipe plug provided with each unit.

Electrical Connections

Electrical conduit connections for conduit fittings accept 1/2″ NPT(M) for NPT versions. The conduit must protect the cable from mechanical damage and terminate in a sealed enclosure or junction box suitable for hazardous locations. For BSPT versions, the cable uses an Ex-D rated cable gland. The fuse holder and 3/10 amp fuse should be used as shown in Fiaure 1. The ground for the CY-DP-03-A must be connected to a true earth ground.

Operating Principle

When the coil is energized, a magnetic field is formed, and the electromagnetic coil generates electromagnetic force to lift the movable core upward, the sealing plug opens, and the liquid flows out from the sealing seat; when the power is off, the electromagnetic force disappears, and the spring behind the movable core presses the movable core onto the sealing seat, closing the liquid channel.

| Material | 430F |

|---|---|

| Connection | 1/4″ |

| Current | 0.75A |

| Fluid | Dual Fluid |

| Max Temperature | 140°F |

| Voltage | DC24V |

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert