Denitrification Spray Lance(CFM Series)

Denitrification spray lance are mostly used in chain furnaces, pulverized coal furnaces, and SNCR denitrification in cement plants, power plants, steel plants, and waste incineration plants to meet NOx emission requirements. It mainly atomizes compressed air and ammonia water to form fine atomized particles, which are then mixed with flue gas to react chemically, thereby purifying harmful gases in the flue gas and meeting the flue gas emission standards.

Design features:

1. Simple structure, not easy to clog

2. Low air consumption, even water distribution

3. Small average particle radius, small particle radius difference

4. Due to the optimized air-water mixing structure, all parts have low loss and long service life

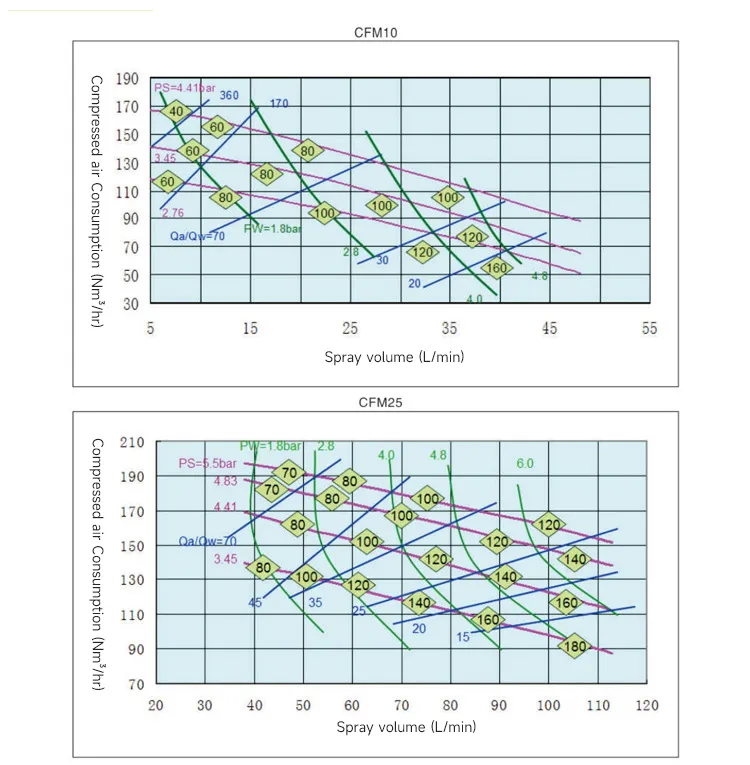

CFM Series Spray Gun Key Features:

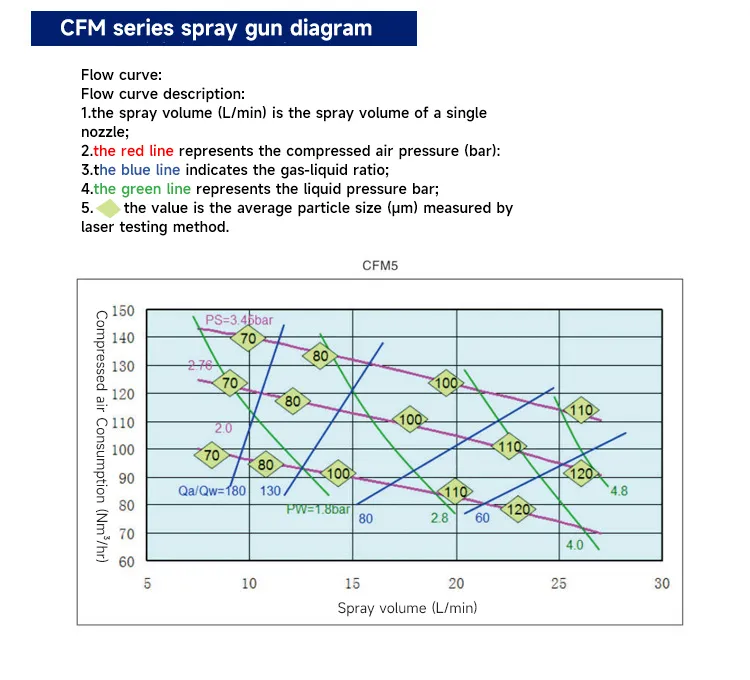

- Strict control of droplet size and spray coverage makes CFM nozzles ideal for flue gas conditioning in furnaces, cooling towers, flues, dryers, etc.

- Multi-stage atomization process produces extremely small droplets using minimal air.

- Fine droplets create more surface area per liter of liquid, allowing complete absorption without wet walls or wet bottoms.

- Higher flow rates ensure stable air pressure regardless of changes in liquid or flow.

- A single nozzle can spray a larger flow rate of water, reducing the total number of nozzles required for cooling.

- 303, 316 and 310 stainless steel are standard materials, with Hastelloy available for more severe environments.

- Extra large free passages allow for more flexibility in water quality requirements.

- Durable components require no frequent maintenance or special tools to replace parts.

- We can provide light standard long-tube spray guns at any time (the gun body can be bent into angles of 0°, 30°, 45° and 90° according to user requirements); we can also customize the design and manufacture of long-tube spray guns that meet strict technical requirements for customers.

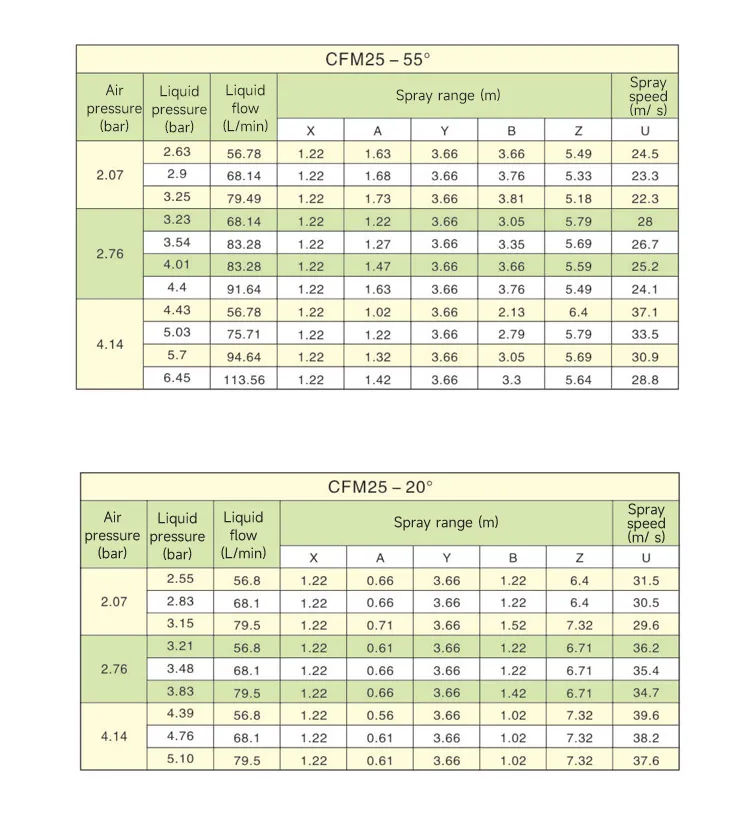

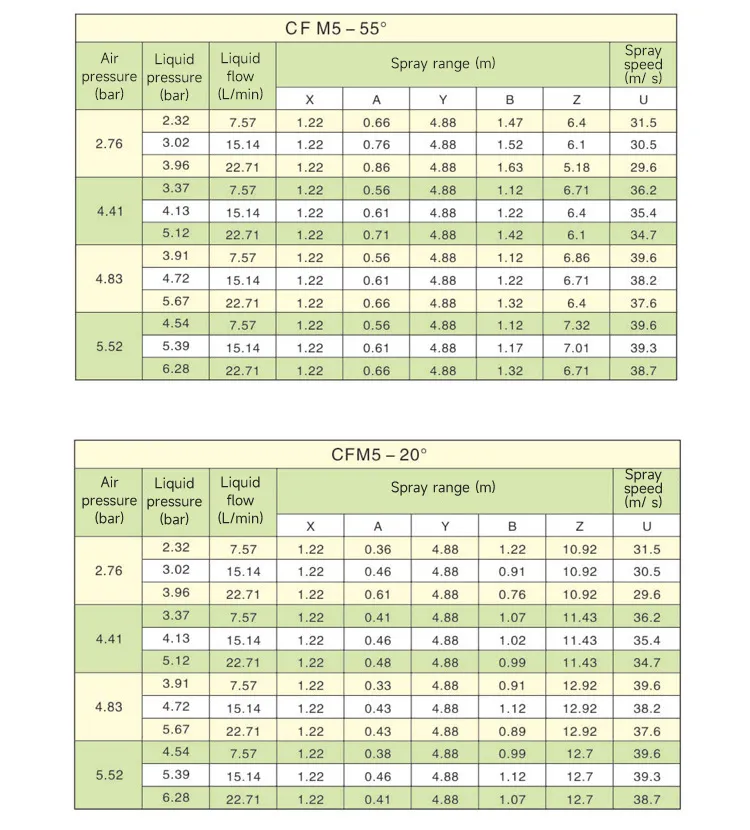

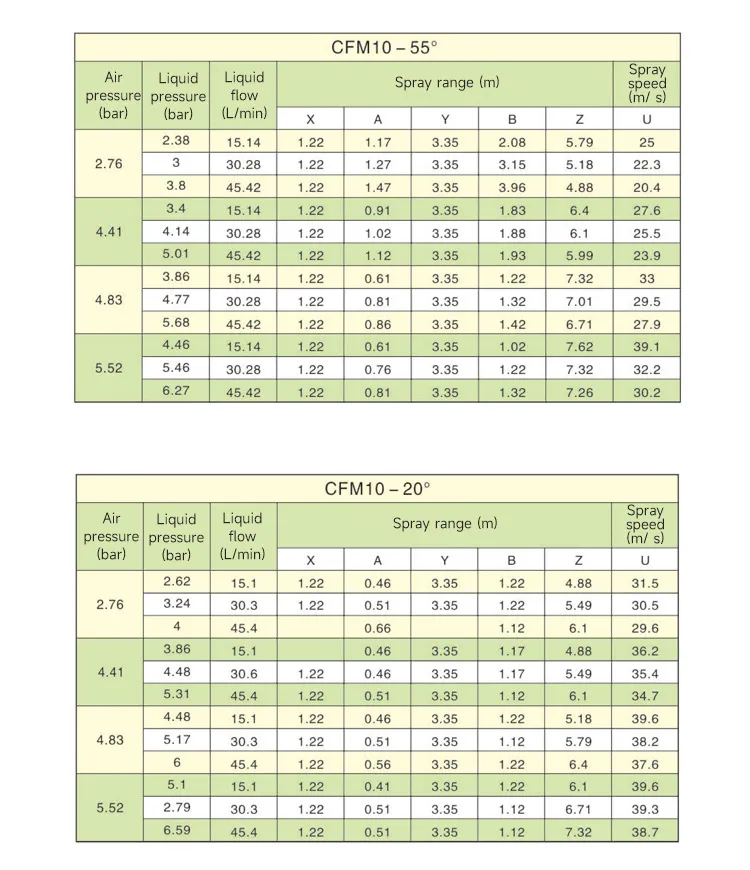

| Spray Angle | 20°, 55° |

|---|

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert