Denitrification Spray Lance(DS Telescopic)

Design features

1. Uniform atomization – the particle size distribution in the entire spray area is uniform, which provides a very superior guarantee for the uniform evaporation and absorption reaction of the liquid. The average particle diameter is only 60μm, and the particle size shall not exceed 120μm

2. Lower operating cost – low gas-water ratio is the advantage of this spray gun, and long-term use can save operating costs

3. Wide flow range – the flow range is from 3L/h to 400L/h, which can meet various flow requirements

4. Long service life – because the nozzle works in a low-pressure environment, the water pressure and air pressure do not exceed 0.6Mpa, so the wear on the nozzle is very small, and the spray gun can also be equipped with a protective sleeve. The nozzle is placed in the protective sleeve, which can better protect the nozzle, thereby greatly extending the service life

5. Convenient operation – it can be controlled on-site or remotely controlled by the central control. It automatically extends to the furnace to spray when in use, and automatically exits the furnace when not in use

Application

Circulating fluidized bed boilers, chain furnaces, biomass boilers, cement kilns, glass kilns and other coal-fired boilers

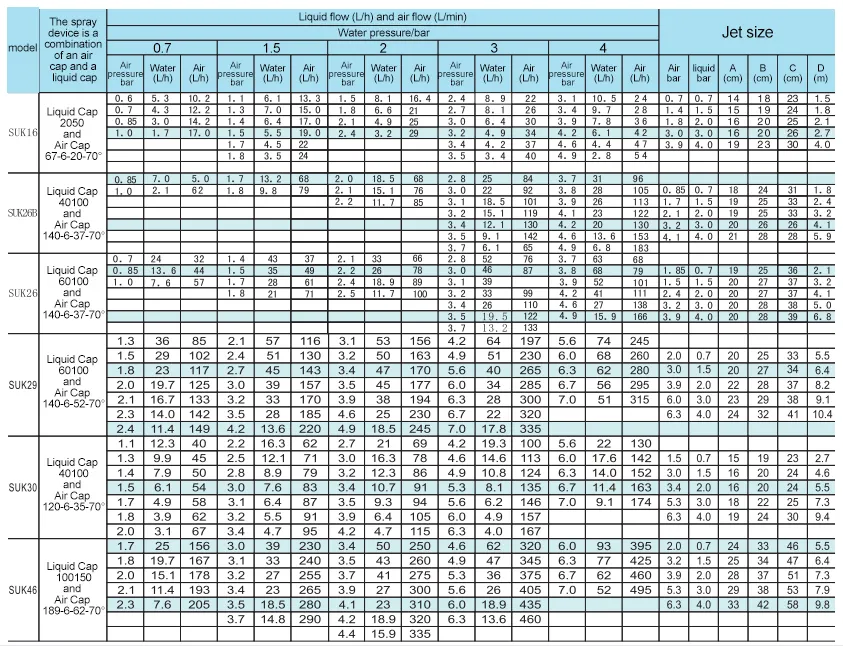

| Min Pressure(bar) | 0.7 |

|---|---|

| Max Pressure(bar) | 4 |

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert