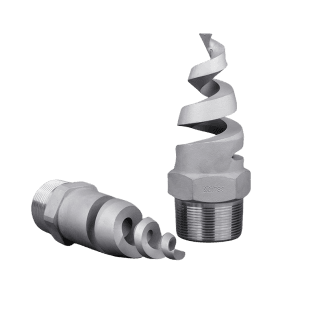

F Type Blowing Nozzle

Design features

1. Made of ABS plastic or aluminum alloy, the nozzle is designed with multiple cylindrical injection holes, from which air is blown out to form fan-shaped and circular air flows

2. The internal structure of the nozzle is designed in accordance with the principles of aerodynamics, which effectively reduces the air resistance during operation, ensuring that the blowing nozzle can obtain high airflow impulse while reducing working noise and air consumption

3. The F-type blowing nozzle is suitable for 1/4-inch BSPT external thread connector and is designed with positioning holes (ABS nozzles) to facilitate the side-by-side installation of the nozzles; the combined wind knife formed by it can produce an effective air curtain

4. The F-type plastic blowing nozzle can withstand an air pressure of 7 bar, and the temperature resistance can reach 77°C at this air pressure.

5. The F-type aluminum alloy blowing nozzle can withstand an air pressure of about 30 bar and can withstand a high temperature of 350°

Common applications

Parts cooling, parts drying, parts washing, material guiding, paper guiding

| Material | ABS Plastic, Aluminum Alloy |

|---|---|

| Connection | 1/4″, BSPT |

| Max Pressure(bar) | 30 |

| Max Temperature | 660°F |

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert