Siphon Air Atomizing Nozzle

Design features

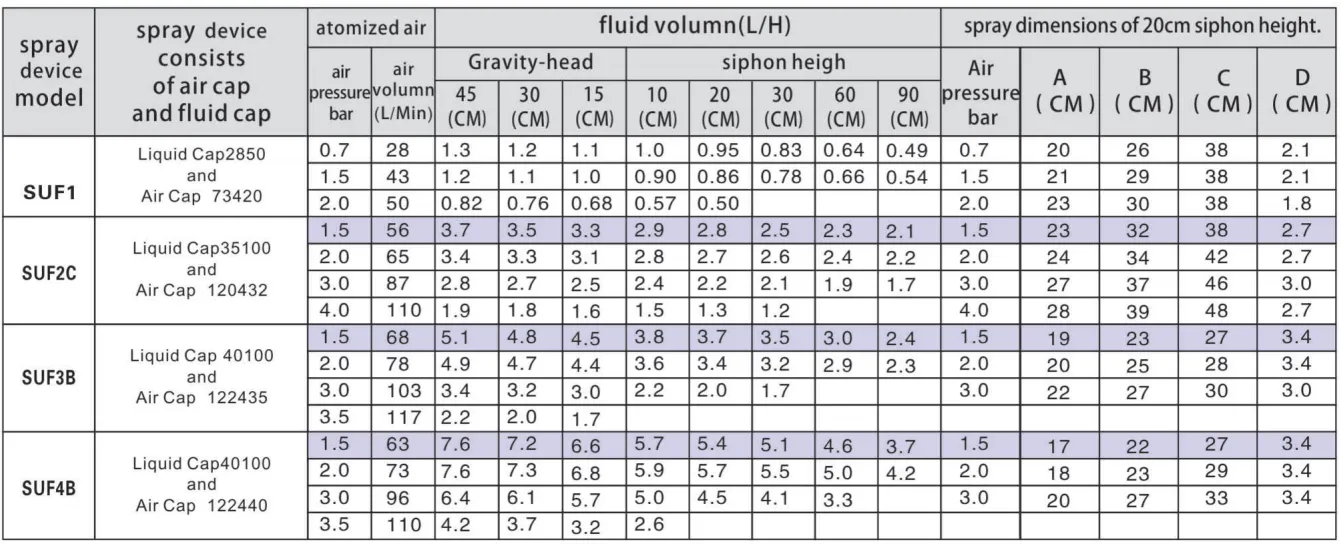

1. The special internal structure design of the air atomizing nozzle can make the liquid and gas mix evenly, producing a fine droplet size spray or a coarse droplet spray. By increasing the gas pressure or reducing the liquid pressure, a finer droplet spray can be obtained, thereby achieving a higher gas flow rate to liquid flow rate ratio.

2. When using a siphon or gravity liquid delivery system, the liquid is supplied by siphon or gravity delivery. In these devices, the liquid is sucked into the gas flow through the delivery pipeline and is atomized in the gas flow.

3. The spray volume is changed according to the different siphon heights. No liquid pressurization is required. The common characteristics of the two fluids: the principle of high-speed flow of compressed air is used to atomize the liquid.

4. It can provide two spray modes: fan-shaped and circular, and has a wide range of flow rates. The inlet connector of the nozzle body has a variety of sizes, suitable for most commonly used pipes.

5. The above nozzle parts are interchangeable, which provides flexibility for obtaining different spray performances.

Applications

Commonly used for spraying, spray humidification, cooling, papermaking, spraying and lubrication, spray dust reduction, disinfection and sterilization, cleaning, air conditioning drainage evaporation, etc.

| Fluid | Dual Fluid |

|---|---|

| Spray Shape | Full Cone, Flat Fan |

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert