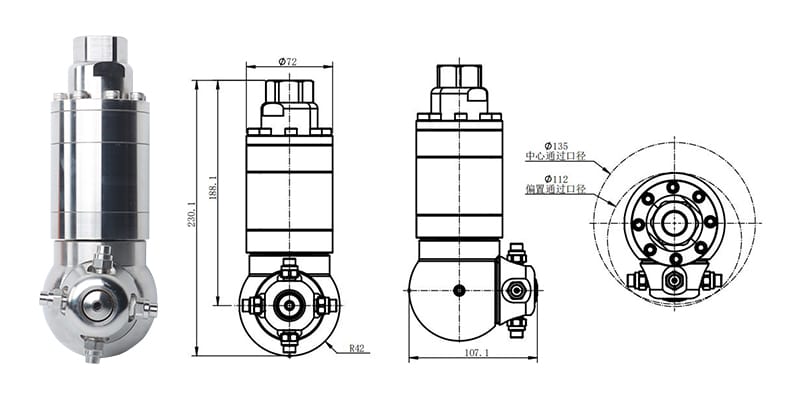

Spray Ball SR42

Compared to low-pressure spray heads, the rotary spray heads SR42 is more water-efficient, provides better and more thorough cleaning, and offers higher cleaning efficiency. It requires no external equipment for operation and only needs to be connected to high-pressure water to perform automatic rotating cleaning.

It is mainly used in the field of cleaning small and medium-sized tanks. It is a fully automatic nozzle that can realize automatic rotation and all-round cleaning inside the tank. Compared with low-pressure nozzles, it saves more water, has better and more thorough cleaning effects, and has higher cleaning efficiency. It does not require external equipment to drive it, and only needs to connect to high-pressure water to achieve automatic rotation cleaning.

CYCO SR42 Rotating Cleaning Head are self-rotating and volumetric, with rotational speed proportional to the inlet flow.

They clean the internal surface of containers and tanks, with complete orbital coverage, in a wide range of applications. The cleaning cycle is completed with two rotations around the vertical axis: after the jets draw a hypothetical sphere once, they hit the same spots for a second time.

Compared to low-pressure spray heads, the rotary spray heads SR42 is more water-efficient, provides better and more thorough cleaning, and offers higher cleaning efficiency. It requires no external equipment for operation and only needs to be connected to high-pressure water to perform automatic rotating cleaning.

Features of the rotating SR42 cleaning ball:

1. It only needs water to drive its own rotation, without the need for external power such as air source or power supply

2. It adopts a unique planetary gear transmission, with a compact structure, strong bearing capacity, and a larger water flow area

3. The leakage point adopts dynamic seal to reduce leakage, save cleaning fluid, and generate greater water flow impact

4. It adopts streamlined nozzle and turbulent linear spray to ensure the concentration of water flow for long-distance cleaning and strong impact

Application:

Widely used for cleaning tanks/kettles/ton barrels/sealed containers in the pharmaceutical, food, beverage, coating, building materials, chemical, pigment, resin, scientific research, dairy, daily chemicals, cosmetics, bioengineering, agricultural engineering, processing tools and other industries

| Cleaning Mode | 3D Rotation |

|---|---|

| Material | 316L, Aluminum Bronze, Engineering Plastics |

| Connection | 1/2" |

| Max Cleaning Diameter | 9.84' |

| Min Entry Diameter | 7.09" |

| Max Temperature | 195°F |

| Min Pressure(bar) | 30 |

| Max Pressure(bar) | 200 |

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert