Steam Rotary Air Nozzle

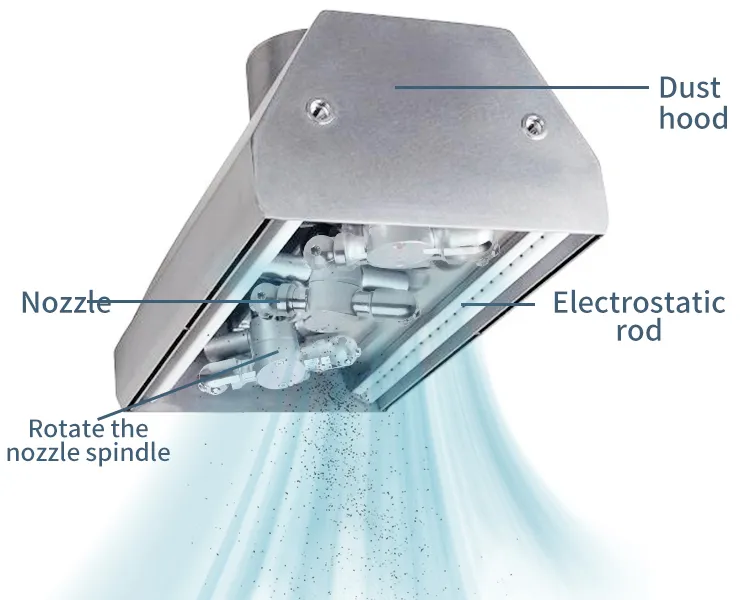

The rotary cleaning high-pressure nozzle is an innovative pneumatic product that specifically solves the difficult problems of dust removal, water blowing, foreign matter removal, drying and static electricity removal in the production and manufacturing of enterprises. It is particularly suitable for the cleaning and drying of special-shaped parts.

Working Principle

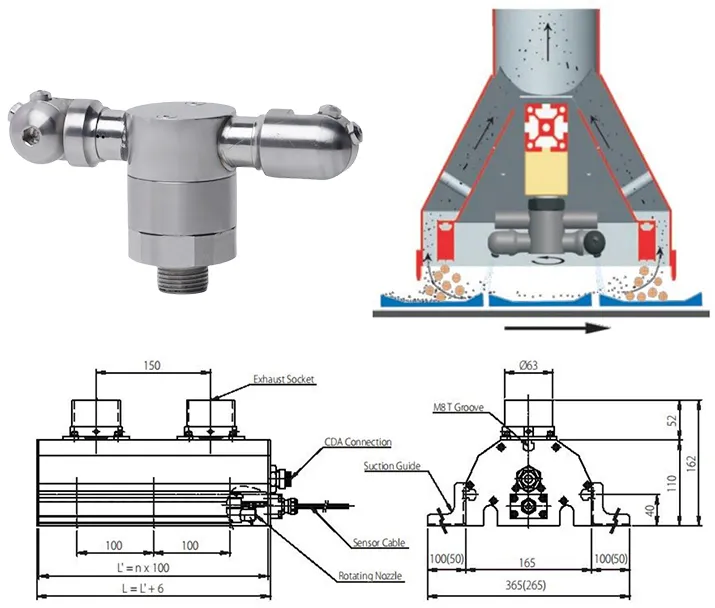

When working, the air is sent out in a spiral shape by the rotation of the outlet air, which produces a fairly high induction ratio, so that the supply air is quickly mixed with the surrounding indoor air. Unlike traditional diffusers, the air outlet slots are arranged radially, and the supply air in the air duct is guided by the air outlet slots to form a jet along the tangential direction. The supply air of the entire air outlet produces a typhoon-like vortex under the action of multiple jets. A negative pressure area is formed in the central area of the vortex, inducing the surrounding indoor air to quickly mix with the supply air, and the entire supply air flow is in a stable horizontal diffusion state. Its induction ratio is 10-20 times that of conventional diffusers. Technical requirements

Product features

1. Multiple specifications to choose from, adapt to different requirements of impact force and low gas consumption

2. Closed structure, powerful vacuum suction expansion slot

3. Ultra-clean nozzle speed and high-precision filtration system foreign matter collection possibility

4. New technology and new concept, in order to provide high quality and reasonable price, provide non-standard customized solutions (maximum 4000MM).

Classification and structural characteristics of swirl vents

According to different use occasions and functions, they can be divided into two categories: fixed swirl vents and adjustable swirl vents;

Fixed swirl vents

The main structural feature is that the air outlet slots are arranged radially.

The most common form is a one-time stamping guide plate like a fan blade. In addition, there are many forms of construction such as a one-time stamping panel; slots are cut on the panel and then guide vanes are added; the throat, guide vanes and diffuser are integrated.

Adjustable swirl vents

The air supply angle can be adjusted by changing the distance and direction of the guide vanes. It is suitable for occasions where both cooling and heating conditions are taken into account and the installation height is greater than 3.8m. The air supply depth can reach up to 20m under winter conditions.

Product parameters

3/8 standard external thread, nozzle aperture is 0.8mm, 1.0mm, 1.2mm, other apertures can be customized

Compressed air requirements

Can rotate normally at 1 bar pressure; at 7 bar pressure, gas flow is 19Nm3/h, use pressure 4-8bar (maximum 10bar)

Applications

Air mixing, dust suppression, humidification, air blowing, cooling, drying

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert