Two-Fluid Air Atomizing Nozzle

Design features

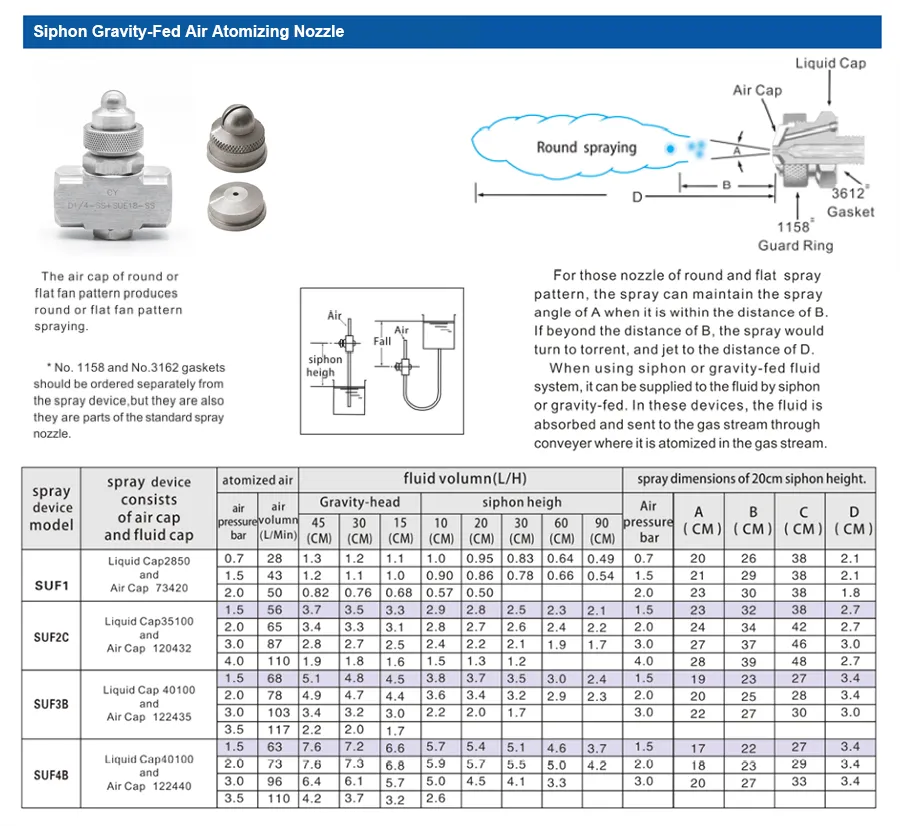

1. The special internal structure design of the air atomizing nozzle can make the liquid and gas mix evenly, producing a fine droplet size spray or a coarse droplet spray. By increasing the gas pressure or reducing the liquid pressure, a finer droplet spray (about 30 microns) can be obtained, thereby achieving a higher gas flow rate to liquid flow rate ratio.

2. The adjustable air atomizing nozzle can adjust the liquid flow rate, and can also produce a spray that meets the requirements without changing the air pressure and liquid pressure, so it has strong adaptability.

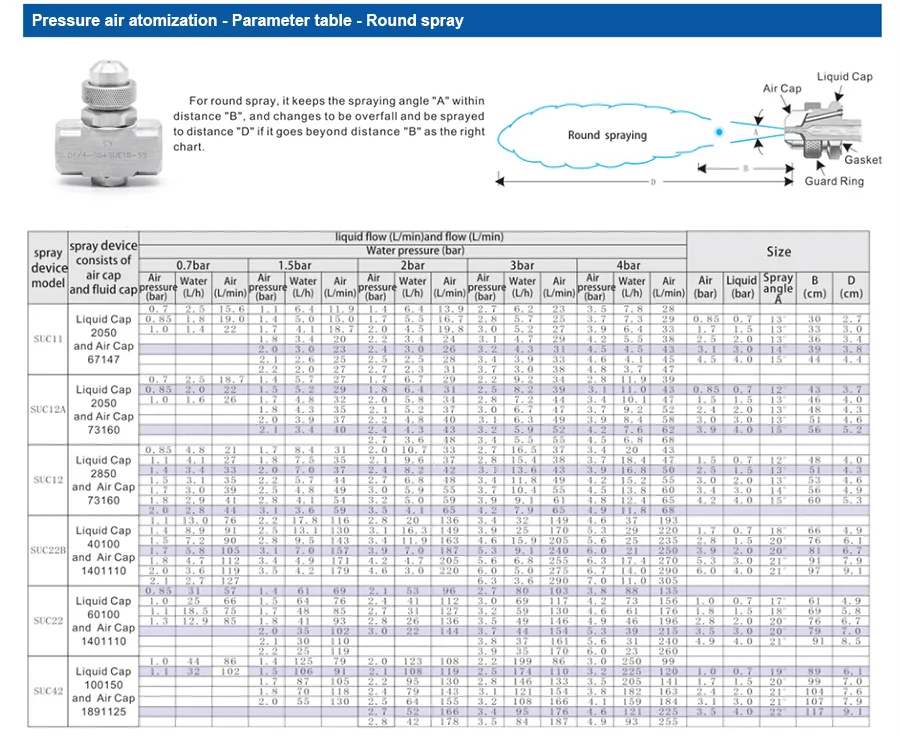

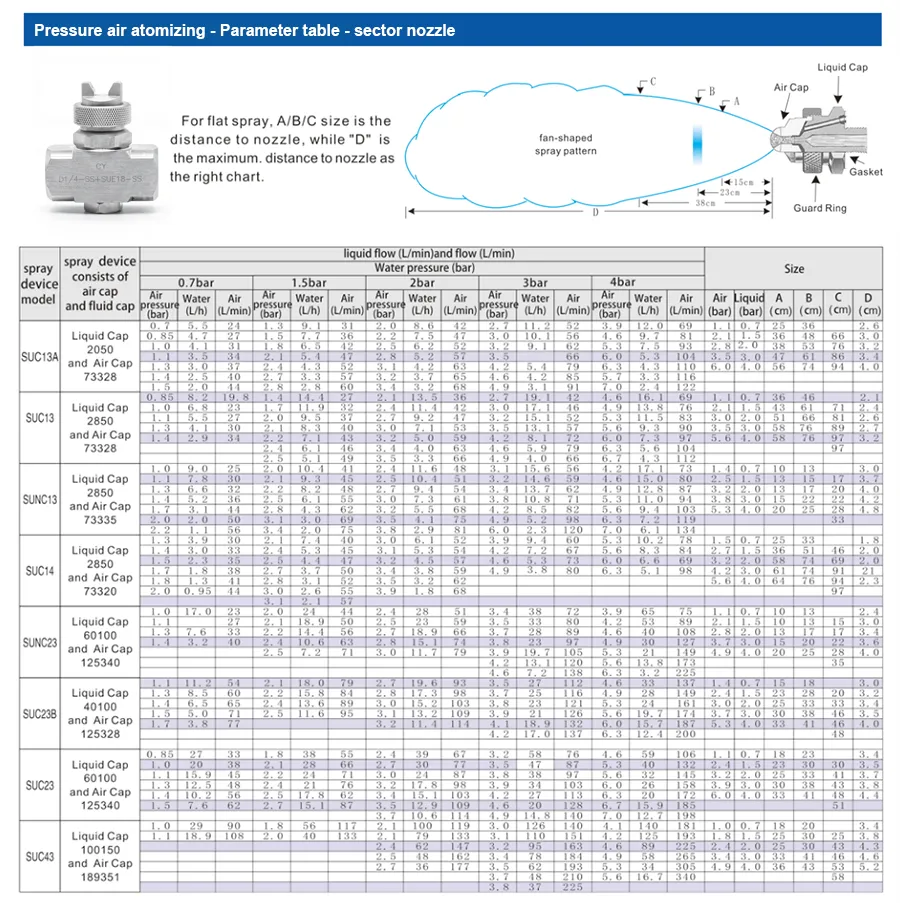

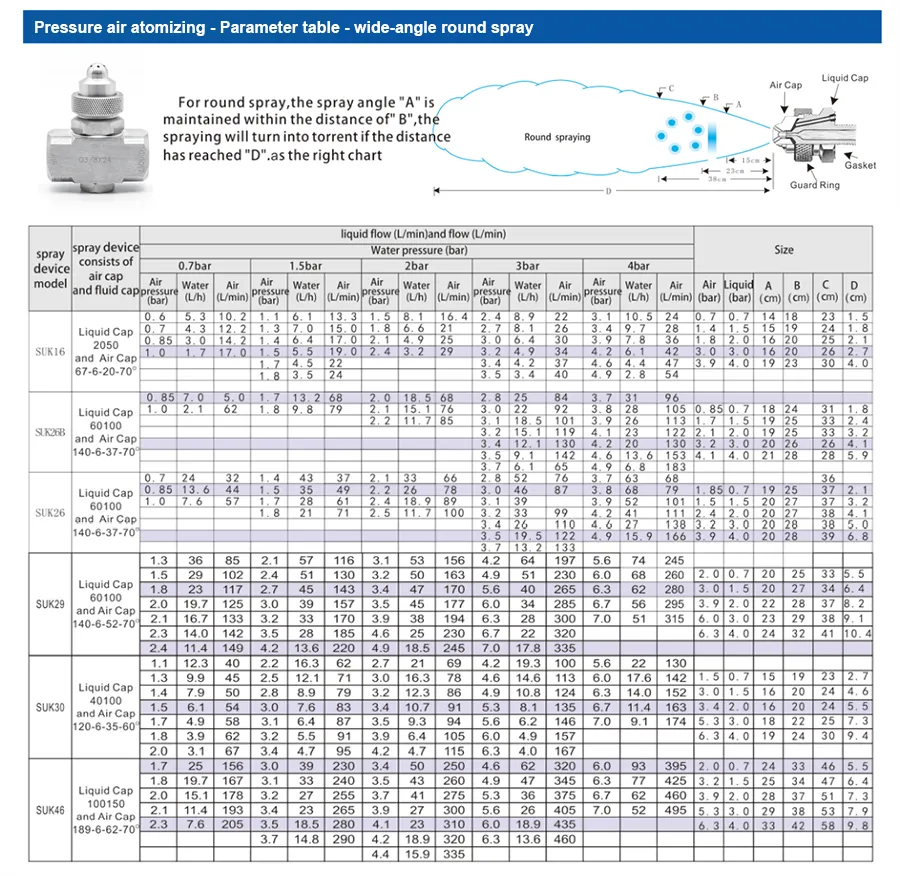

3. It can provide three spray modes: fan-shaped, circular, and wide-angle circular, and has a wide flow range. The inlet joint of the nozzle body has a variety of sizes, suitable for most commonly used pipes.

4. The above nozzle parts are interchangeable, which provides flexibility for obtaining different spray performances.

Applications

Papermaking: pulp moisture control, release agent spray, etc.;

Steel: cooling of plates and pipes, etc.;

Printing: preventing heat waves in gravure rotary printing machines, etc.;

Cleaning: precision substrates, glass panels, etc.;

Cooling: molds, castings, car bodies, coatings, etc.;

Automobiles: cooling of trolleys in ovens on coating lines;

Plastics: antistatic agent spray, coating films, etc.;

Textiles: moisture control and moisturizing of yarns and fabrics, etc.;

Coating: release agents, deodorants, oils, surface treatment agents, rust inhibitors, lubricants, honey, insect repellents;

Humidification, disinfection, dust removal

| Fluid | Dual Fluid |

|---|---|

| Spray Shape | Full Cone, Flat Fan |

Customization Request

Can not find the product you need? Get a personalized customization plan.

Contact SupportApplication Solutions

We provide professional customized product application solutions.

Contact an Expert